COMPANY’S INFRASTRUCTURE

MACHINE SHOP

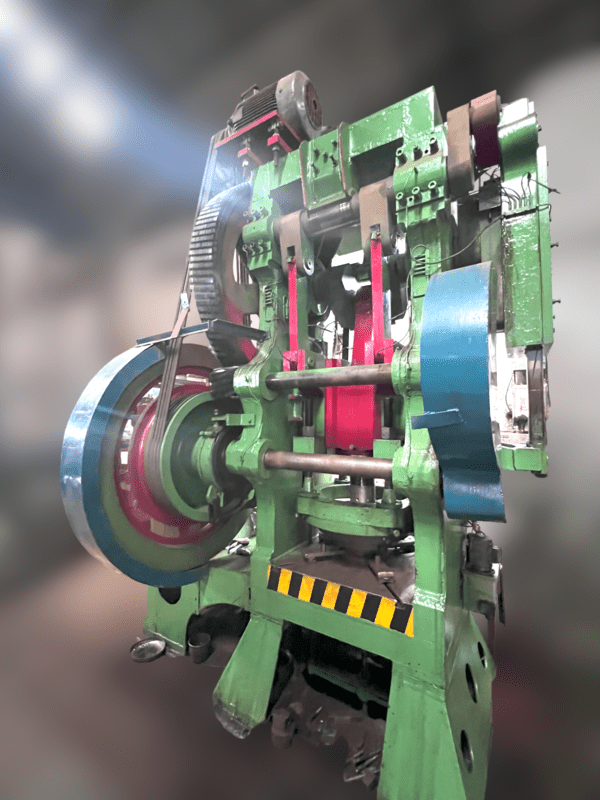

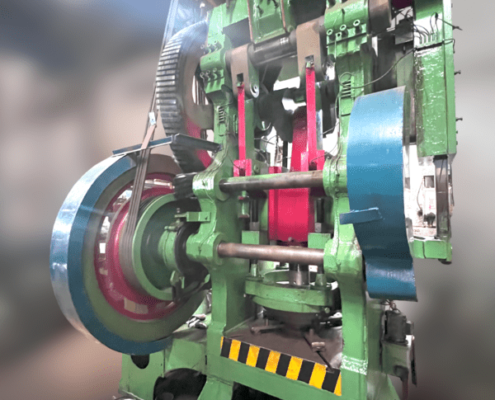

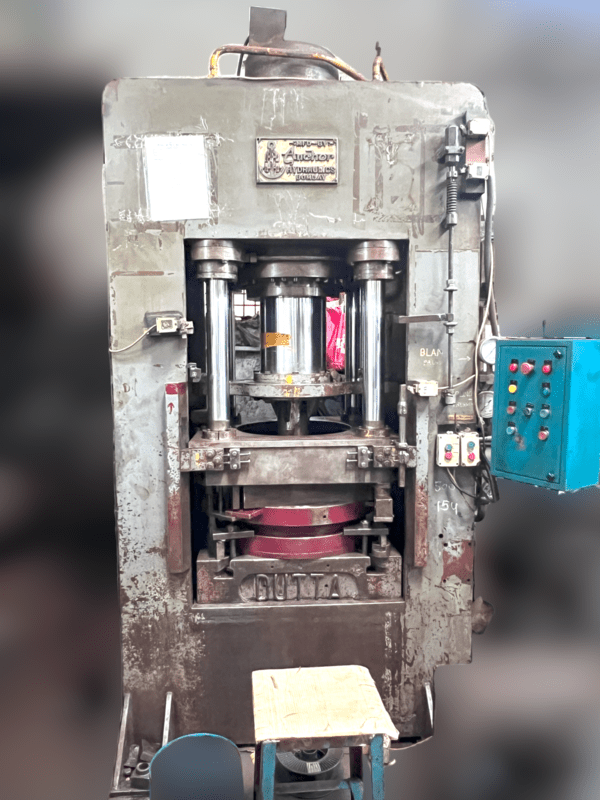

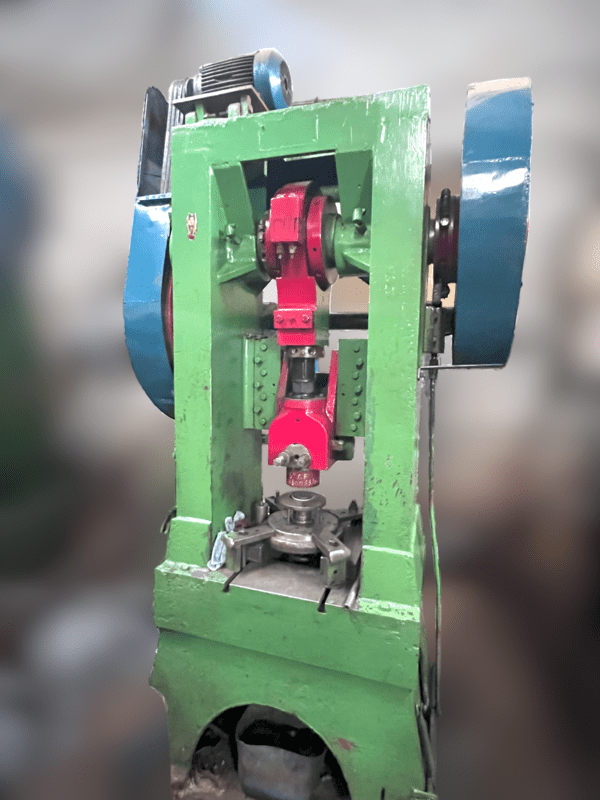

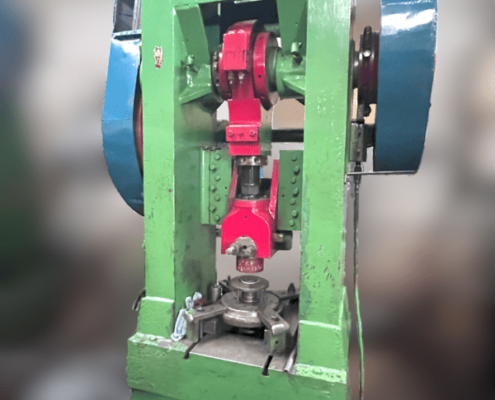

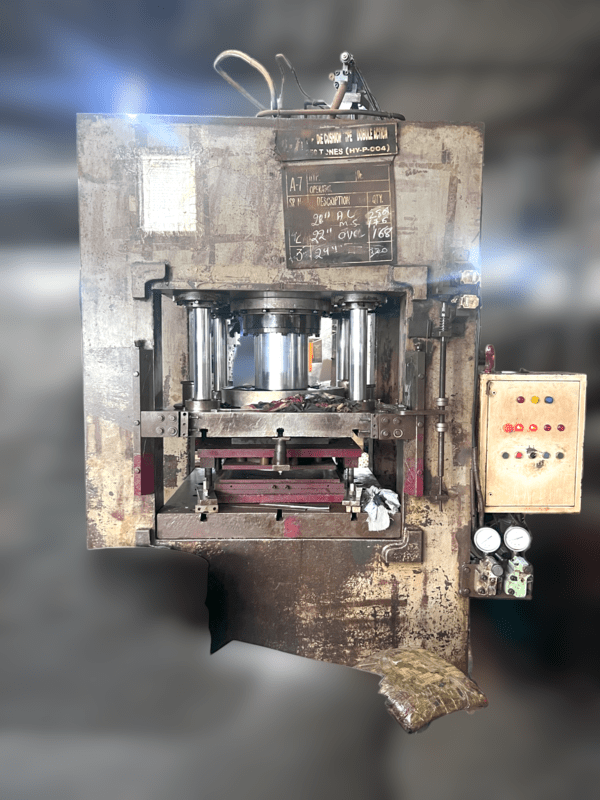

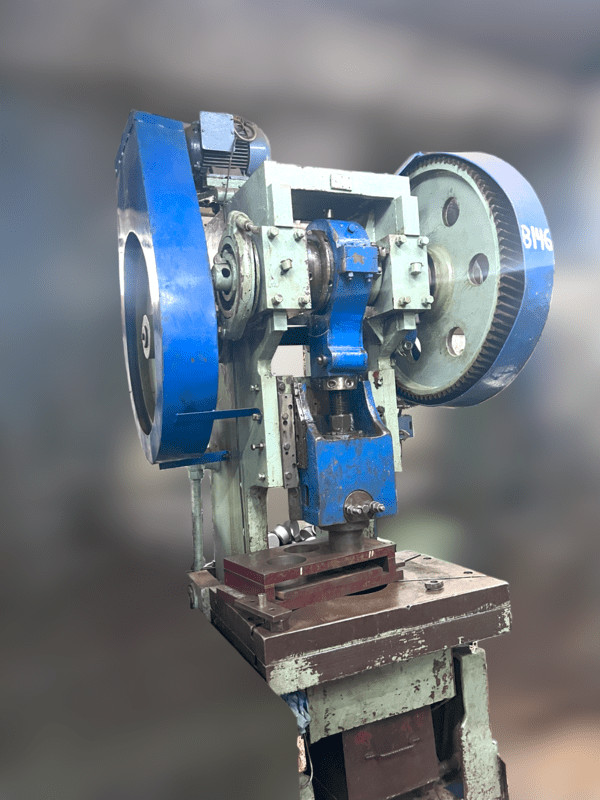

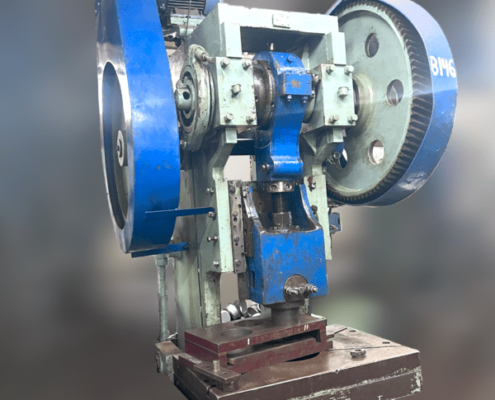

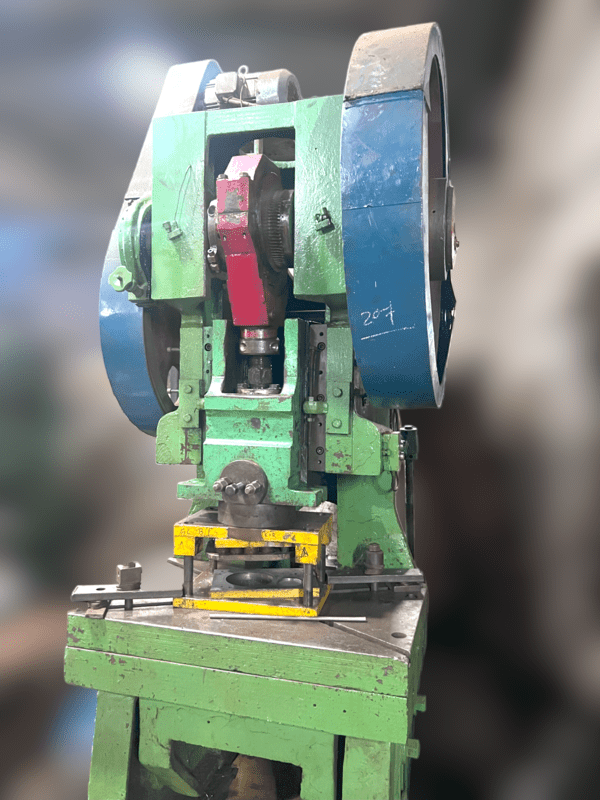

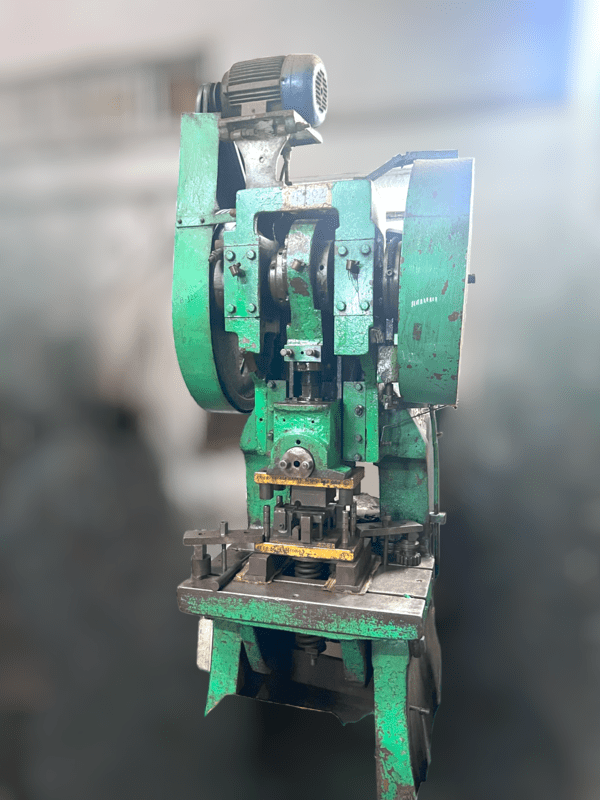

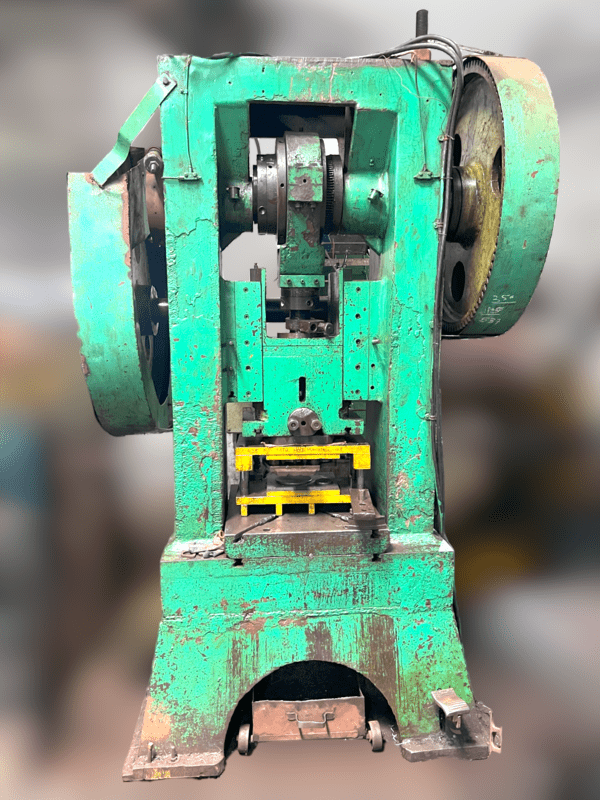

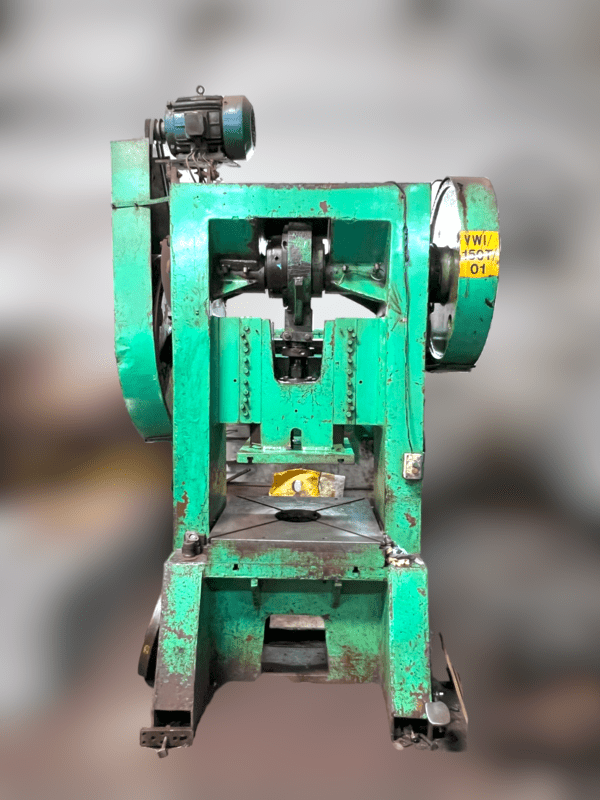

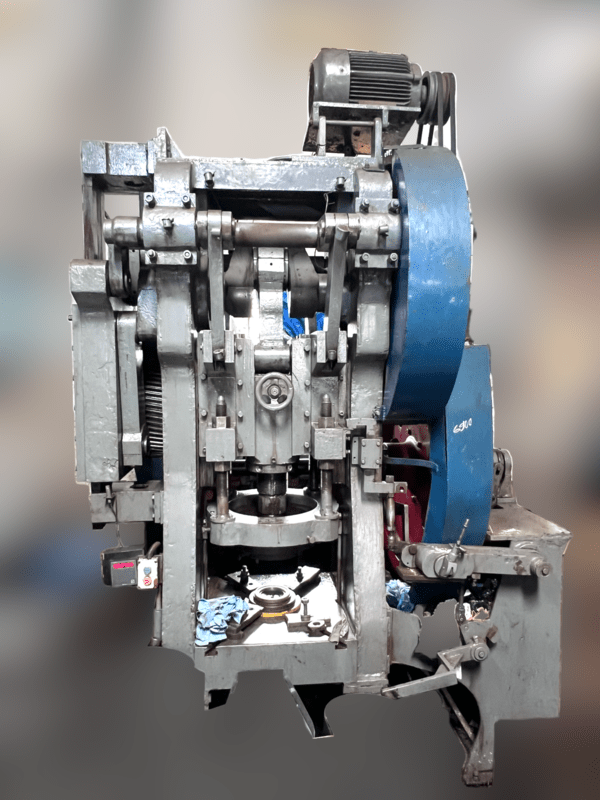

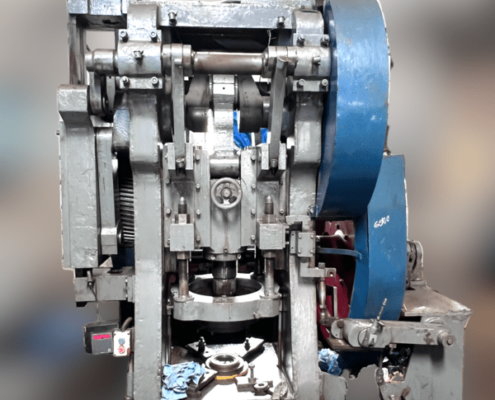

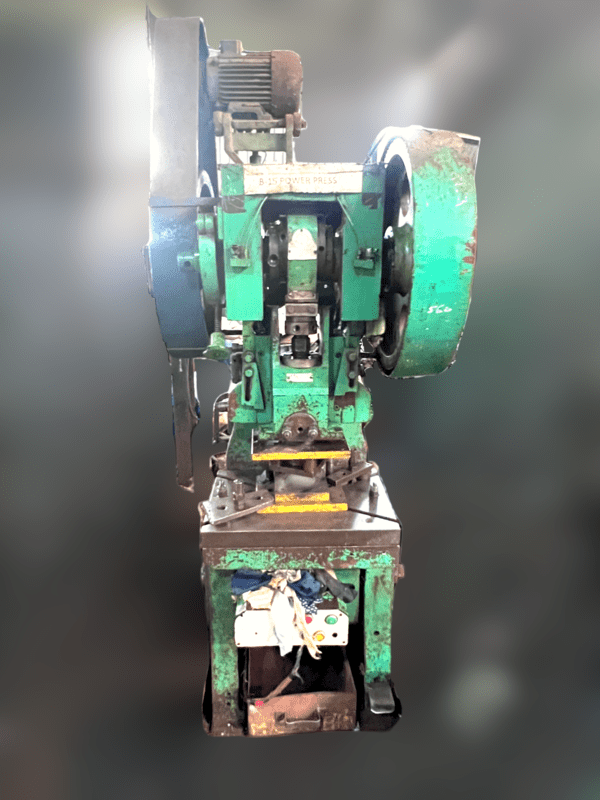

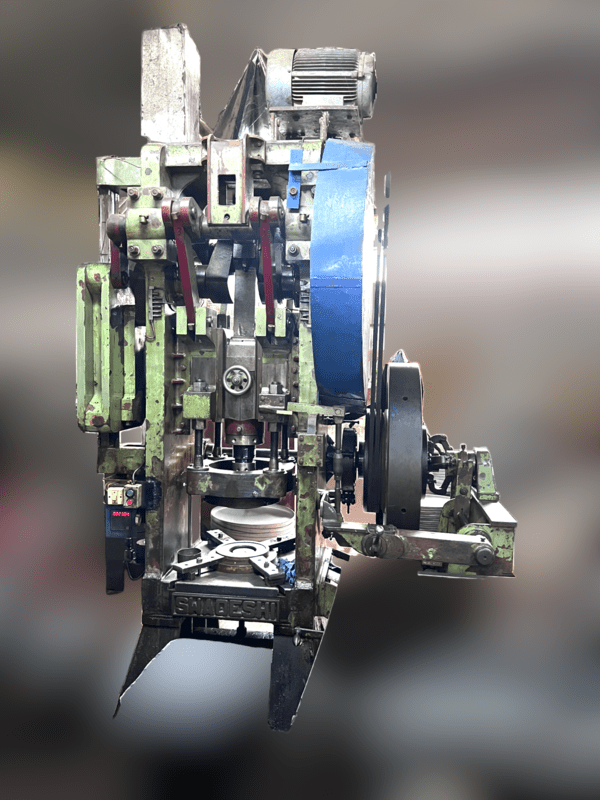

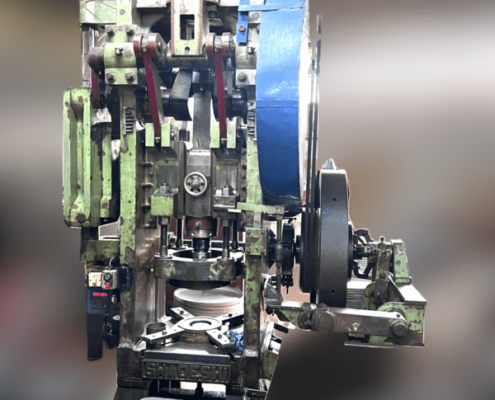

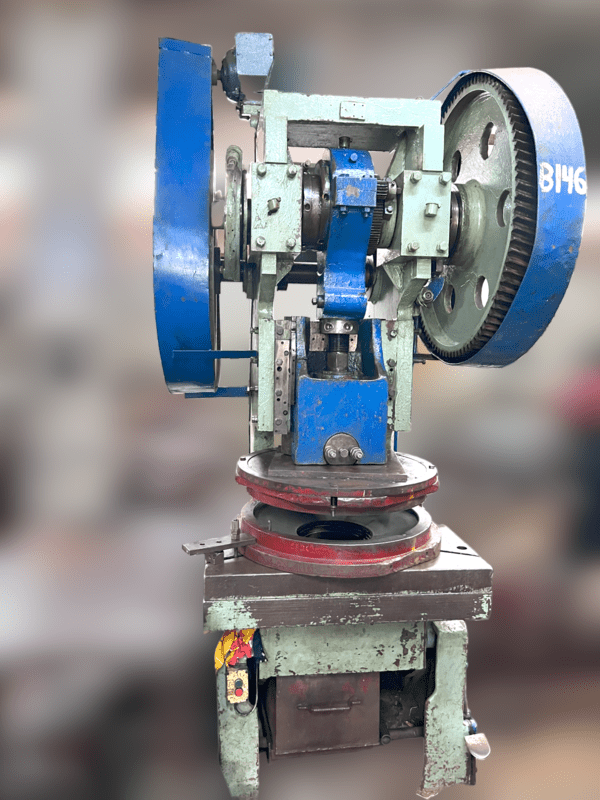

Atai boasts an extensive and diverse range of cutting-edge press machines that form the backbone of its robust manufacturing infrastructure. From the precision of the Deep Draw Hydraulic Press and the adaptability of the Deep Draw Press Toggle Type to the sheer power of the Mechanical Press and the Hydraulic Press with Die Cushion, Atai’s machinery is designed to handle a wide spectrum of production challenges with remarkable efficiency and accuracy.

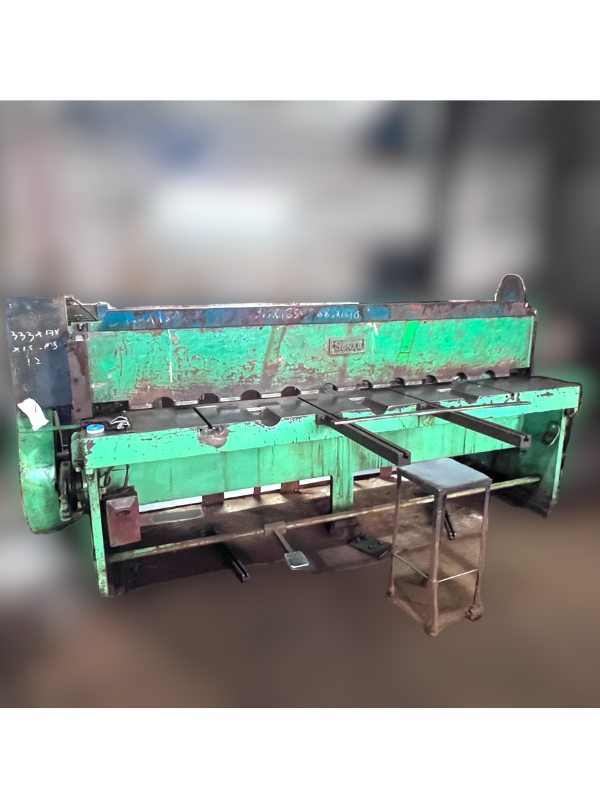

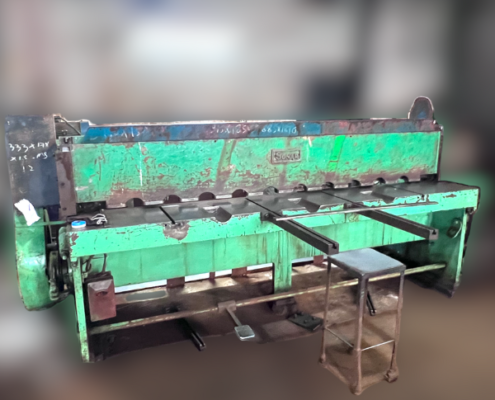

Complementing these press machines, Atai’s specialized equipment like the Perforation Machine and Shearing Machine facilitate intricate perforation and precise sheet metal cutting, respectively. The inclusion of the Spinning Lathe allows for intricate shaping and forming, while the Laser Marking Machine ensures impeccable product traceability and branding.

Incorporating advanced technology, Atai’s Circle Cutting Machine ensures precise circular cuts with consistency, adding another layer of versatility to its manufacturing capabilities. This comprehensive array of press machines underscores Atai’s commitment to providing solutions tailored to diverse industries, empowering businesses to elevate their production processes and achieve exceptional results.

- Deep Draw Press Hydraulic – 150 – 200 Ton

- Deep Draw Press Toggle Type – 70 – 150 Ton

- Mechanical Press – 15 – 200 Ton

- Hydraulic Press with Die Cushion – 250 Ton

- Perforation Machine – 50 Ton

- Shearing Machine – 1250mm x 3.5mm & 2500mm x 3.5mm

- Spinning Lathe – 3 No

- Laser Marking Machine

- Circle Cutting Machine – up to 36”

- Welding

a. Spot Welding – 4 Nos

b. Projection Welding – 50KVA

c. CO2 Welding – 3 Nos

d. Gas Welding – 2 Nos